SLS (Selective Laser Sintering) – выборочное (селективное) лазерное спекание порошков на основе полиамида. Порошок раскатывается равномерным слоем по всей платформе рабочей камеры принтера, после чего лазер запекает только те участки, которые соответствуют сечению модели на этом слое на заданной высоте.

Применение

Прототипирование по технологии SLS на сегодняшний день является одним из наиболее выгодных видов изготовления прототипов по 3D-моделям.

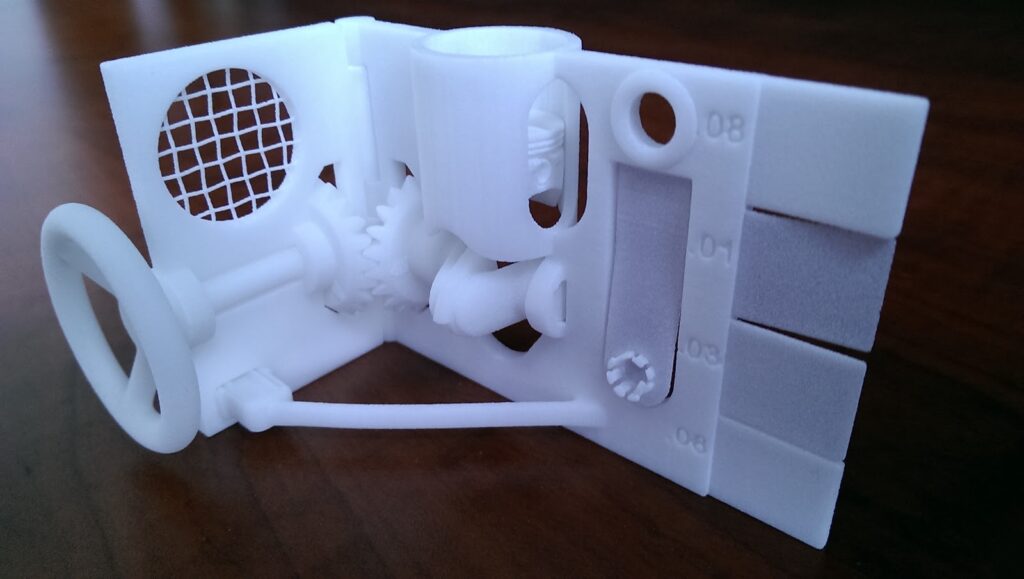

Чаще всего эту технологию применяют при создании макетов и функциональных прототипов с геометрией любой сложности. Модели могут выполнять свои функции как образцы для испытаний, как детали конечного продукта или быть воплощением дизайнерской идеи.