SLM – метод аддитивного производства, использующий лазеры высокой мощности для создания трехмерных физических объектов за счет плавления металлических порошков компании ФИТНИК.

ПРИМЕНЕНИЕ

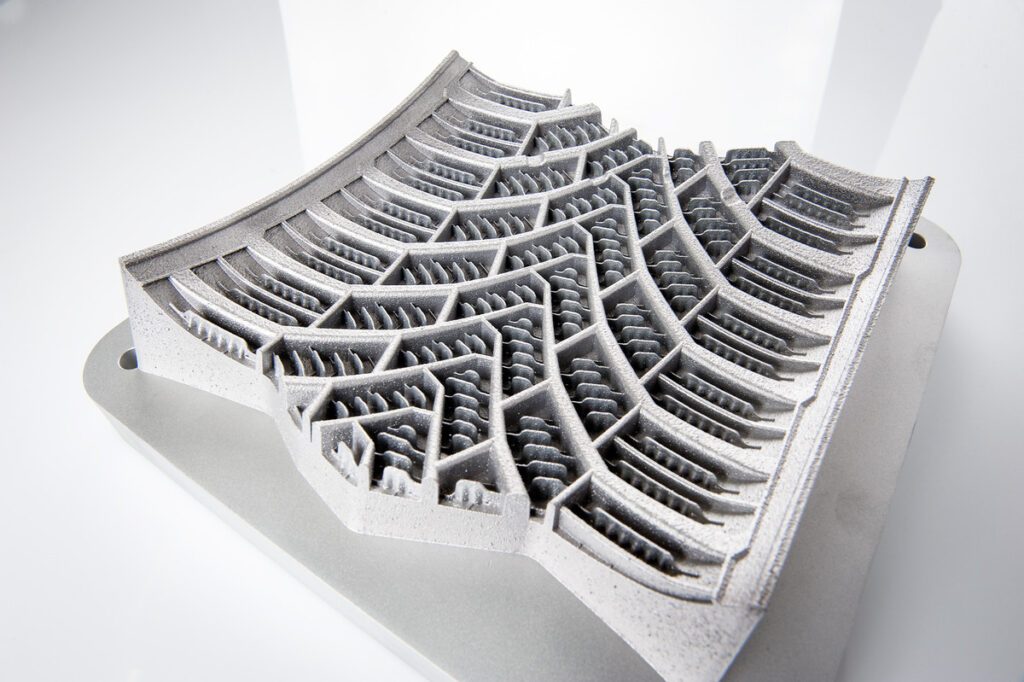

Технология SLM применяется для построения объектов сложной геометрической формы, зачастую с тонкими стенками и полостями. SLM успешно применяется в аэрокосмической отрасли, позволяя создавать высокопрочные элементы конструкций, недосягаемые по геометрической сложности для традиционных механических методов изготовления и обработки (фрезеровки, резки и т.д.). Готовые изделия имеют высокое качество, их механическая обработка практически не требуется. Дополнительным положительным эффектом является экономия материалов, поскольку SLM является практически безотходным производством. Возможность комбинирования гомогенных и пористых структур в одном объекте полезна при создании имплантатов – например, ацетабулярных чашек или других ортопедических имплантатов с пористой поверхностью, способствующей остеоинтеграции (сращиванию с костной тканью)