Специалисты ФИТНИК помогут Вам решить следующие задачи:

- Провести анализ существующих деталей и конструкций на целесообразность применения аддитивных технологий при их производстве;

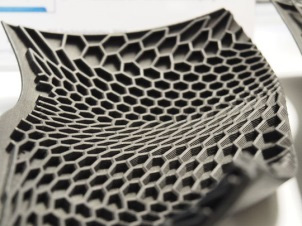

- Доработать или спроектировать новую деталь (узел, изделие), чтобы она полностью удовлетворяла условиям аддитивного производства: эффективное уменьшение веса конструкции, уменьшение количества деталей в сборке, создание сетчатых структур и другое;

- Подобрать материал и технологию аддитивного производства, а также последующий метод обработки для получения качественного конечного изделия (готовой детали);

- Подготовить 3D-модели к производству с учётом всех требований выбранной технологии и материала. Это позволит избежать ошибок до начала производства;

- Изготовить детали (узлы, изделия) на сертифицированном производстве, имеющем большой парк аддитивного и обрабатывающего оборудования, с контролем качества выпускаемой продукции;

- Оказать помощь по эффективному внедрению аддитивного производства на предприятии.

Аддитивные технологии позволяют сократить и упростить процесс выпуска на рынок нового продукта. Применение аддитивных технологий помогает внедрить прорывные идеи в дизайне, самолетостроении, машиностроении и других отраслях.

Проектирование для аддитивного производства имеет ряд преимуществ:

С появлением аддитивных технологий стало реальным и доступным производство конструкций с бионическим дизайном. Конструкции с бионическим дизайном – это детали со сложной геометрией и ячеистыми структурами, максимально облегченные при помощи топологической оптимизации. Уменьшение веса изделия позволяет сократить расход материала и время изготовления. Вследствие этого уменьшается стоимость производимой детали. При этом деталь имеет функциональные и механические свойства, как при традиционном производстве.